Detailed Guide to Climbing Harnesses

I. Why Harnesses Are Necessary

In the early days of mountaineering, harnesses were not used. Climbers tied ropes around their waists, and belayers relied on friction around their hips for protection.

However, the flaws of this method are evident: the ribs endure increased pressure, causing intense pain that persists even after climbing.

Worse, a fall could be fatal. A moderate fall with a force of 3.7 KN can render a climber unconscious or even lead to death within minutes due to extreme tension concentrated on the waist.

Thus, the ultimate purposes of harness design are to withstand fall forces and distribute pressure.

II. Harness Design

Modern climbers rely on harnesses, which have become indispensable.

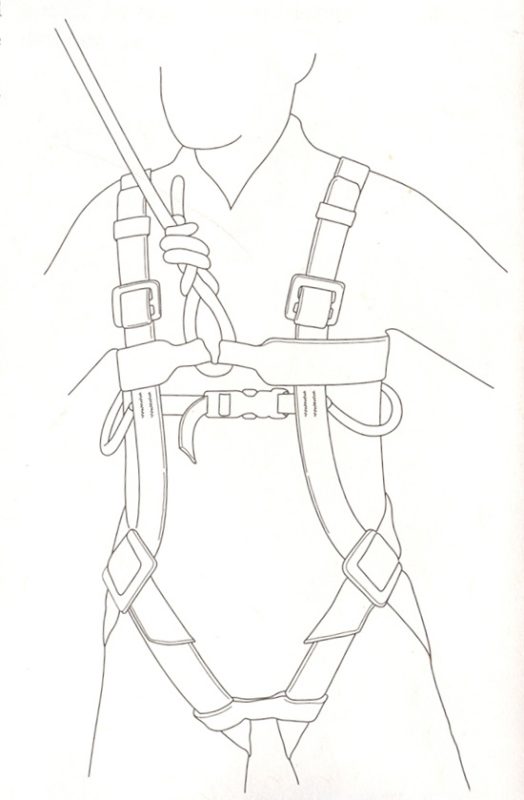

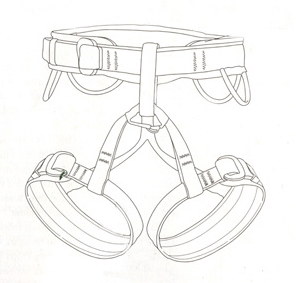

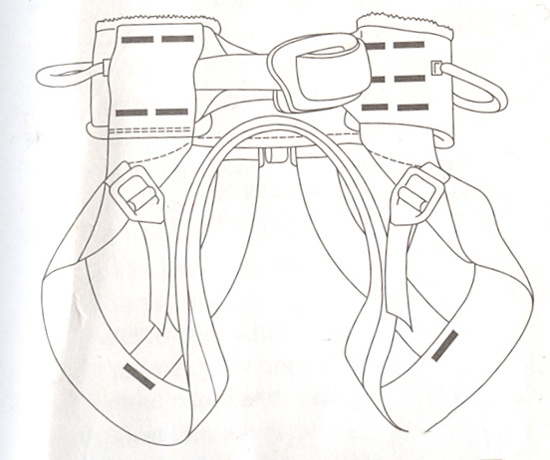

A typical harness includes thickened waist padding, leg loops, belay loops, and gear loops.

These features enhance comfort and safety during descents, falls, or hanging operations.

Today, harnesses are specialized for sport climbing, big-wall climbing, or mountaineering, though high-quality harnesses often accommodate multiple needs.

There are two fundamental harness designs: full-body harnesses and sit harnesses.

- A full-body harness distributes force vertically and evenly across the legs, chest, and back. However, during severe falls, it may rotate excessively, causing dizziness or neck injuries. Due to high cost and inconvenience, full-body harnesses are now primarily used in industrial or team-building settings.

- Sit harnesses, paired with a chest harness (replaceable with a long sling or backpack straps), have become mainstream.

Sit harnesses come in two styles: the “diaper-style” (with a strap running between the legs to connect to the waistbelt) and the “Swami” style.

- The diaper-style has largely disappeared from Western markets due to discomfort during hangs, lack of built-in belay loops, uneven force distribution, and potential injury risks during falls. Modified versions are still used in mountaineering.

- The Swami-style, introduced by Trailwise in 1967 and popularized by Forrest, remains dominant. Key considerations when purchasing a Swami harness include waistbelt design.

A well-designed waistbelt typically measures 8–11 cm wide at the back and 4–5 cm at the front, balancing comfort and safety. Optimal back width (e.g., 8 cm with good ergonomics) outperforms excessively wide but poorly designed alternatives.

III. Leg Loop Options

Leg loops are categorized as non-adjustable, semi-adjustable, or fully adjustable.

- Non-adjustable loops are lightweight and ideal for sport climbing.

- Semi-adjustable loops (adjustable within ~8 cm) offer a snug fit for most climbers.

- Fully adjustable loops (up to 15 cm or more) accommodate seasonal clothing changes but are slightly heavier.

Regardless of type, leg loops 6–8 cm wide provide optimal comfort, especially for heavier climbers. Narrow loops (<5 cm) can dig into the legs during prolonged use. Harness weights range from 85–310 g, with minimal perceptible difference unless engaging in extreme climbs.

IV. Materials and Construction

Most harnesses use ~3 cm webbing for load-bearing sections. Wider webbing reduces manufacturing costs but compromises comfort, leading some brands to combine wide rear webbing with narrower front sections.

Early padded harnesses stuffed fabric or foam into tubular webbing. Modern standards involve molded foam sandwiched between fabric layers, precision-cut and stitched via computer-controlled machines. Some manufacturers vary foam thickness or add air vents via heat-molding to enhance breathability.

Durability depends on foam density. Soft foam degrades quickly under pressure, while stiffer, crush-resistant foam ensures longevity. High-wear areas (e.g., tie-in points) are reinforced with durable fabric or double-layered webbing.

Exterior surfaces, especially leg loop bases, may use abrasion-resistant materials like Cordura or flight suit fabric. Edges are often bound with additional webbing, though internal stitching provides smoother contact with skin.

Lining materials should remain soft and comfortable even when sweat-soaked. Plush linings, while soft, retain moisture and may freeze in cold conditions.

V. Harness Usage

Most modern harnesses require a back-threaded buckle for closure.

However, some designs feature auto-locking buckles that remain secure when tightened or loosened.

Buckles are typically aluminum or steel; CE-certified models withstand forces far exceeding real-world demands (e.g., 7 kN from a 100 kg climber in a 1.5 fall factor vs. 10 kN rated strength).

VI. Harness Maintenance

1. Faded or aged harnesses may still function, but industry guidelines recommend replacement after 2–3 years of moderate use or 5 years of light use.

2. Retire harnesses after a severe fall, visible damage (e.g., fraying, cracked buckles), or significant UV degradation.

3. While older harnesses (>7 years) can be used for top-roping (no falls), avoid prolonged exposure to acidic substances or extreme heat (e.g., car trunks), which degrade nylon invisibly.

4. Common accidents stem from improper buckle threading. Ensure the tail extends ≥8 cm and avoid distractions while donning. Always perform partner checks.